Long Harmony Automation Equipment: What is the reason why the feeder is popular

2020-06-23(2280)Views

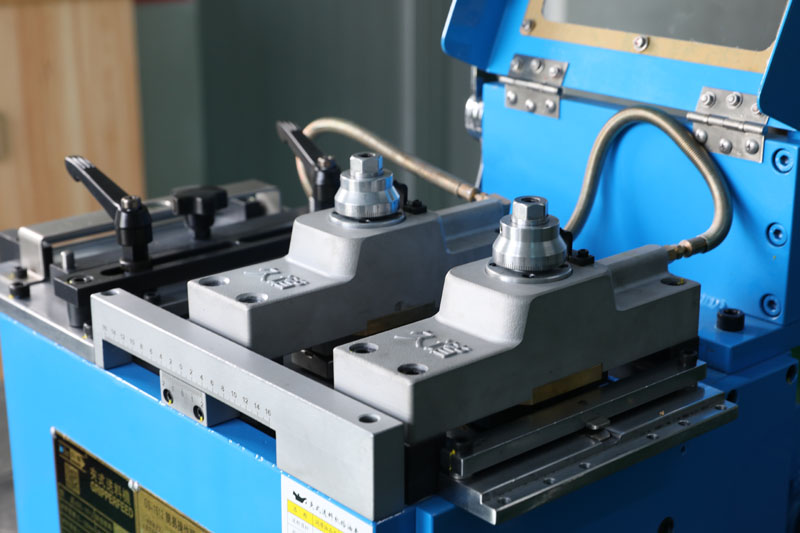

The three-in-one feeder is divided into three types: standard, medium and thick plates, which are distinguished according to the thickness of the applicable data. The standard three-in-one feeder is suitable for the automatic production of 0.3-2.2mm thick thin plate materials.

1. Small wear, low failure rate and long service life. Choose the optimized structural design, all parts and wear parts are selected to the highest professional standards, and have a fully automated lubrication oil supply system, which ensures that the machine has little wear and failure rate, and maximizes the guarantee of the machine Service life.

2. The structure is compact and the floor space is small. During the planning of the traditional split punching production line, a long waiting area needs to be reserved between the three equipments of the data rack, leveler and feeder. The thicker the data, the more waiting area is required, and sometimes even More than 10 meters, this has always affected the customer's plan and space plan, and the three models are integrated into one, the structure is compact and completely does not require a waiting area, which can maximize the use of customer plant space.

3. Low labor intensity and high output power. The three-in-one feeder combines the three functions of material rack, leveling and feeding on the same machine, which can completely automate the completion of all production processes such as data loading, uncoiling, feeding, leveling, feeding, etc. The material operation can now be easily set by one person on the electric control console, which reduces the labor intensity and increases the output power.

4. The wide range of application makes it possible to automate stamping of thick plate materials. In fact, it is an automatic equipment specially developed for the automatic processing of thick plate materials. It is not only capable of processing thin and medium plate materials that can be processed by traditional stamping automated production lines, but also thick plate materials that can not be processed. The largest The thickness of applicable materials can reach 12mm.

Recommended News

-

Defects and elimination of clip feeder

As a high-precision feeder specially adapted to the use of h...

-

The difference between pneumatic relaxation and mechanical relaxation of servo feeder

The biggest difference between the mechanical NC feeder and ...

-

Long Harmony Automation Equipment: What is the reason why the feeder is popular

The three-in-one feeder is divided into three types: standar...

-

Long Harmony Automation: Advantages of various feeders

Air feeder: The air feeder is the earliest feeding equipment...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073