Long Harmony Automation: Advantages of various feeders

2020-06-23(2283)Views

Air feeder: The air feeder is the earliest feeding equipment used in the stamping industry. Its principle is to use the air source as the power, clamp the material through the cylinder

1. Air feeder: The air feeder is the earliest feeding equipment used in the stamping industry. Its principle is to use the air source as the power, clamp the material through the cylinder, and feed the material by the telescopic stroke of the cylinder. Adjust the feed length by adjusting the cylinder The length of the trip is controlled. Advantages of air feeder: easy to operate, easy to install, affordable, and automatic stamping feeding equipment at the lowest price. In actual production, it is mainly used for feeding stamping products with low precision and low speed.

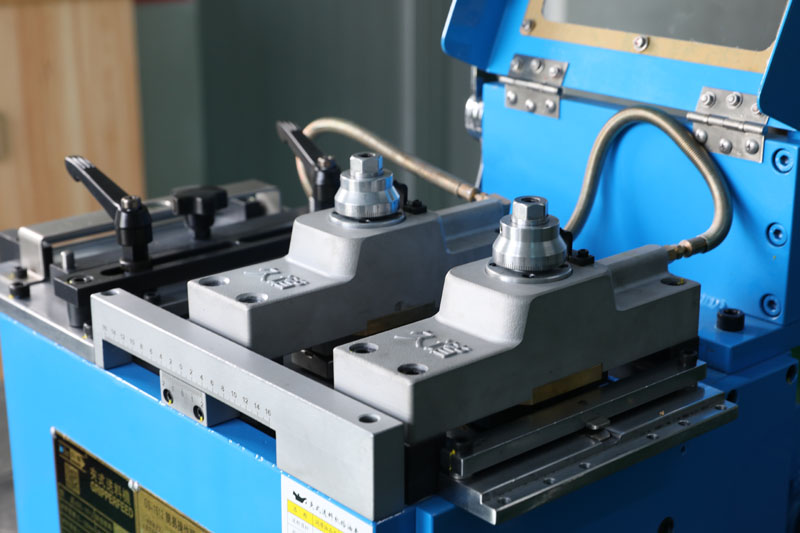

2. High-speed roller feeder: The roller feeder is currently the most widely used feeding equipment. Its principle is to connect with the output shaft of the press through a connecting rod, which is driven by the punching of the press. The feeder is adjusted by adjusting the deflection amplitude of the eccentric disk. Feed length. Advantages of high-speed roller feeder: high feeding accuracy, fast speed, no additional energy supply, and extremely low failure rate.

3. The principle of the NC servo feeder is that the servo motor and PLC control system drive the upper and lower rollers to rotate and compact by controlling the synchronous belt, so as to achieve quantitative feeding. NC servo feeder advantages: dual control mode of button and touch screen, easy operation, servo control, higher feeding accuracy, simultaneous multi-stage feeding, convenient setting of feeding length, maximum feeding length of up to 9999.99MM, can achieve wider and feeding Stamping industry with long steps.

Recommended News

-

Defects and elimination of clip feeder

As a high-precision feeder specially adapted to the use of h...

-

The difference between pneumatic relaxation and mechanical relaxation of servo feeder

The biggest difference between the mechanical NC feeder and ...

-

Long Harmony Automation Equipment: What is the reason why the feeder is popular

The three-in-one feeder is divided into three types: standar...

-

Long Harmony Automation: Advantages of various feeders

Air feeder: The air feeder is the earliest feeding equipment...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073