What are the classification and advantages of the three-in-one feeder?

2020-06-23(2274)Views

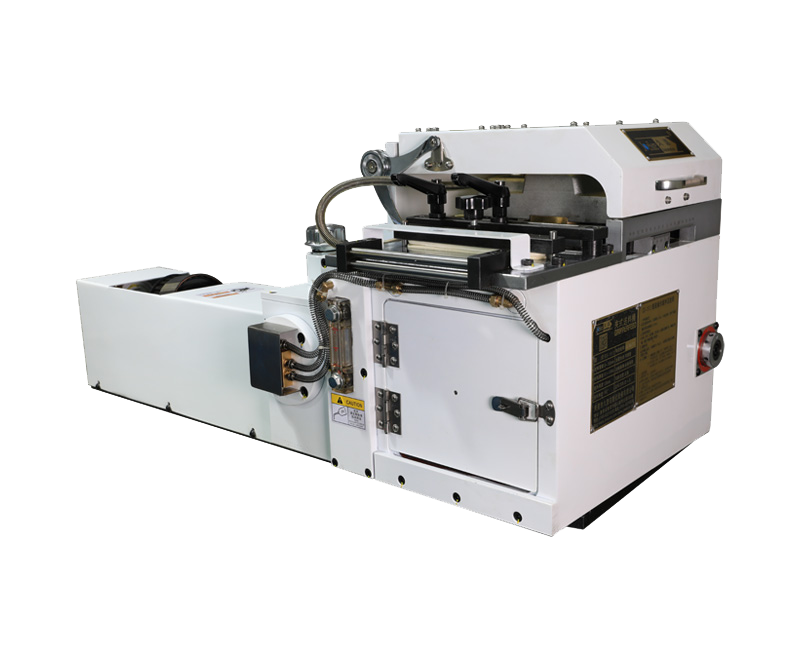

The three-in-one feeder is a highly efficient feeding equipment developed for the stamping industry. It is a three-in-one machine that uses raw materials as rolling materials

The three-in-one feeder is easy to operate and has truly realized automation, which greatly saves labor and reduces labor intensity. Although the split stamping production line can also be automated during operation, it requires a series of operations, such as manual feeding, pulling, individual adjustment, machine testing, and refilling.

Therefore, it is impossible to truly realize automatic production, and the three-in-one feeder is a device that realizes automatic operation. Feeding, feeding, blocking, folding, leveling, feeding, and refilling can be done by one person through point control operations on an independent console, which greatly saves labor and reduces labor intensity. Adopt computer numerical control system, more humanized design, suitable for feeding and calibration of various metal plates.

The three-in-one feeder has a wider range of application, and can process thick plates and high-strength metal thick plate materials. These materials cannot be processed by separate stamping production lines. They are suitable for feeding and correcting various metal plates.

As long as the split stamping line is suitable for thin and medium plates below 4.0 mm, once the thickness is thick and the material rigidity is large, it cannot be used for processing and production, so many customers can only buy plates and manually feed for stamping production, and the three-in-one The emergence of the feeder fundamentally solves this processing problem. Its maximum servo material thickness reaches 13.0 mm, which can be applied to the processing and production of various high-strength plates and automate the processing and production of thick plate materials.

Recommended News

-

What are the classification and advantages of the three-in-one feeder?

The three-in-one feeder is a highly efficient feeding equipm...

-

High-tension board three-in-one feeder is the future development trend

Stamping forming is an important forming method in modern ma...

-

Selection of high-speed roller feeder

The high-speed roller feeder is the most widely used feeder ...

-

Clip feeder-the preferred feeder for high-speed punches

The high-speed punching machine is the most commonly used pr...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073