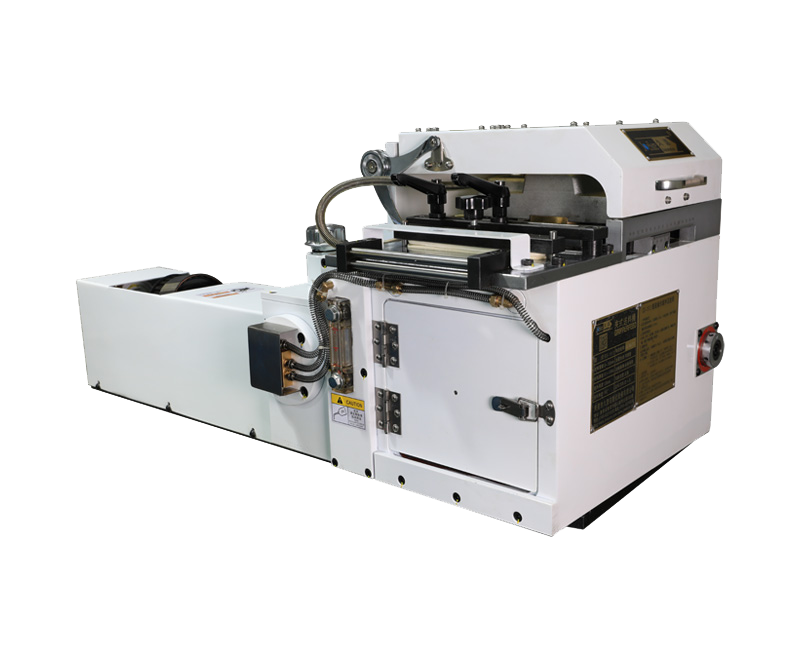

Clip feeder-the preferred feeder for high-speed punches

2020-06-23(2286)Views

The high-speed punching machine is the most commonly used production equipment for sheet metal processing. Its punching speed is fast. If the traditional single-punch processing technology is used, it will not fully exert its own value of efficient processing. Therefore, it is generally equipped with a data rack, a leveler, and a feeder.

There are many types of feeders on the market, mainly including air feeders, roller feeders, NC servo feeders, and long harmonic clamp feeders. In order to truly play the efficient function of high-speed punch presses, clamp feeders It is undoubtedly the first choice for deployment. Its unique high speed, ultra-high stability and low failure rate are unmatched by several other types of feeders. Compared with other feeders, the high-speed punching machine equipped with a long harmonic clamp feeder has six major functional advantages:

1. The "relay race" type of data feeding method can reach a speed of 1200 times per minute. It can completely complete the synchronous punching and feeding action with the high-speed punching machine to maximize the output power.

2. The feeder has high accuracy, stability and reliability. The main body of the clip feeder adopts an integrated molding structure, and no resonance occurs at all during the stamping process of the cooperative high-speed punch, which determines the complete stability of the feeding accuracy.

3. The operation and conditioning are concise. The feeding step and relaxation point of view can be adjusted in real time during the stamping process to maximize the useful working time.

4. The scale-type step adjustment method, the operation is simple and clear, high precision, reducing the labor intensity of the operator.

5. Connected to the output shaft of the press through a belt, no rated power is required, the work is quiet and silent, and the energy saving and environmental protection are truly completed.

6. The clamping force can be adjusted according to the characteristics and thickness of the data, so that the data will not be indented or deformed during the feeding process, so that the high-speed punch can be used to stamp the electroplated data, red copper, aluminum alloy, alloy, etc. The sensitive raw material tape improves the application scope of the stamping production line.

Recommended News

-

What are the classification and advantages of the three-in-one feeder?

The three-in-one feeder is a highly efficient feeding equipm...

-

High-tension board three-in-one feeder is the future development trend

Stamping forming is an important forming method in modern ma...

-

Selection of high-speed roller feeder

The high-speed roller feeder is the most widely used feeder ...

-

Clip feeder-the preferred feeder for high-speed punches

The high-speed punching machine is the most commonly used pr...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073