The principle of the clip feeder

2020-07-03(1804)Views

The production of stamping is moving towards high speed and high precision. There are more and more occasions where high-speed punching is used during stamping production. The maximum number of strokes of high-speed punching machine can reach 1200 times/min. At this moment, if using traditional air feeder and roller feeding The machine and the NC feeder can fully exert the high-speed punching machine\'s efficient function.

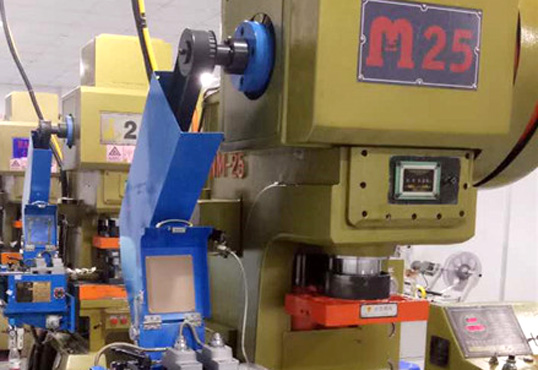

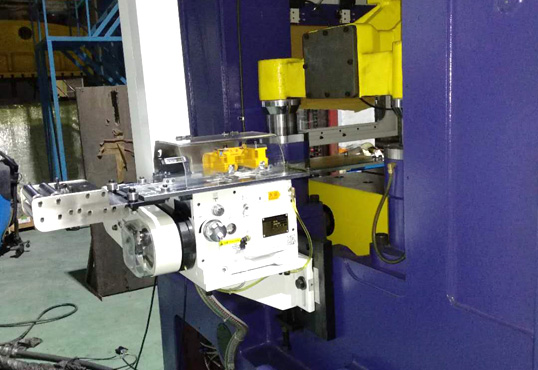

The clip feeder is a high-efficiency feeding device developed for high-speed stamping. It uses a mechanical stamping and feeding linkage structure, and the feeding can reach up to 1200 times per minute, which completely completes the intention of synchronous feeding with a punch. In use, the clip feeder is fixed to the side of the punch table with a fixed plate and an L-shaped bracket, and at the same time, it is connected to the punch output shaft with a timing belt to achieve a mechanical transmission effect, allowing the data to pass from left to right Relax the gripping clamp and adjust the tension of the drive timing belt.

Make it run synchronously with the output shaft of the press, and the phase difference between the two remains the same. Then use a quick gauge to set the feed length, set the feed thickness through the dial on the reverse clamp bracket, and then start the clip feeder.

When the upper die of the punch presses the data, the cycloid cam of the feeder is at the starting point of the equal diameter. At this moment, the cam rolls and the data does not move. The punch presses the data until the cam passes the end of the equal diameter. The cam continues to roll and push The slider moves along the slide bar to disengage the chuck from the data. When the cam continues to rotate through 180 degrees, the data is stuck in the chuck of the next station.

At this moment, the upper die exits, and the cam continues to roll, which in turn drives the clamping rod. The clamping rod pushes the data to move to the next station. When the data moves to the next station, the punch presses down again and the work cycle is completed. High-speed active feeding of stamped data.

Recommended News

-

One-feed one-pull punch feeder

In addition to the conventional automatic feeding method of ...

-

Large deflection material rack with deflection NC servo feeder

The large deflection data rack with deflection NC servo feed...

-

The principle of the clip feeder

The production of stamping is moving towards high speed and ...

-

Functional knowledge of active feeder

The active feeder is used as a machine to transmit data. Occ...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073